Space Management represents an area of opportunity for Retailers and Manufacturers to collaborate to Improve Shopper Satisfaction.

Retailer and Manufacturer investments come together at the shelf — where Shoppers meet products face-to-face and most importantly, where purchase decisions are made.

So who needs to Understand the shelf?

In many organizations, it's left to the shelving or planogram team, typically in a tactical approach, where the focus may be more on the number of planograms that can be pumped out and less on the strategic considerations of merchandising and the Retailer’s Shopper.

Leaving the shelf to a small team limits many organizations’ opportunities associated with moving to a more strategic approach to shelving.

Merchandising is regaining importance, particularly as it relates to Shopper-centric merchandising models. Increased fragmentation in demographics, blurring of traditional boundaries between marketing channels, and new software and technologies available in the industry are resulting in a shift in thinking on merchandising best practices.

Dramatic shifts in consumer demographics and Shopper behavior have reduced the effectiveness of the more traditional retail strategy of providing a standard assortment and shelf layout across the entire retail chain.

The opportunity?

Increase broad, strategic understanding and improve approaches to managing the shelf, leading to smarter choices and recommendations which focus on Shopper satisfaction, and ultimately, enhance business results.

Here are some resources to help you get started:

- Course Video Preview: Space Management

- *NEW* Master’s Course: Space Optimization and Advanced Technologies

How YOUR organization can become more strategic at the shelf …

Planograms (POGs) are more than pretty pictures—or they should be!

Did you know there are different types of POGs – and they are intended for different purposes? For example, an image POG is meant to be a pretty picture, possibly when selling in a shelving concept, vs focusing on the specifics of the planogram.

Image POGs are the most common type developed – often with more concern that all of the live images are nicely displayed in the POG than the strategic thought below the surface.

Here are some other types of POGs that can be created:

- Display POGs, which are great for planning how the Retailer is going to merchandise their display areas in the store, and to ensure compliance at store level.

- Schematic POGs are meant for the retail store, with easy to understand layouts of the planogram for ease of implementation.

- Analysis POGs have performance metrics mapped onto them to assess results, and may include highlighting overstocks and understocks, as an example.

There are also many powerful analytic reports available, which should always be reviewed and understood when planograms are developed. These reports are only as valuable as the inputs you put into the POG (see tip #2 below).

POGs require the right inputs

What requirements do you think are necessary to complete a category planogram? You may have answered accurate product information – including product dimensions, UPC codes and live images. Also, the products need to be arranged on shelves so accurate Retailer’s fixture dimensions, including section sizes, gondola measurements and shelf measurements can be verified. Without accurate product and fixture information, the POG will not physically work.

There are some other inputs you may not have thought of, including:

- Retailer’s shelf strategies. Different Retailer strategies can directly affect the shelf layout and overall targets and objectives for a planogram. This includes Private Label strategies, target Shopper and Shopper decision trees, the role of the category, store clusters, and shelving standards. Without consideration for the Retailer’s unique strategies, the chances of the POGs being implemented in retail stores is very low. The more fine-tuned a Retailer’s shelving strategies are, the better the POGs are likely to be.

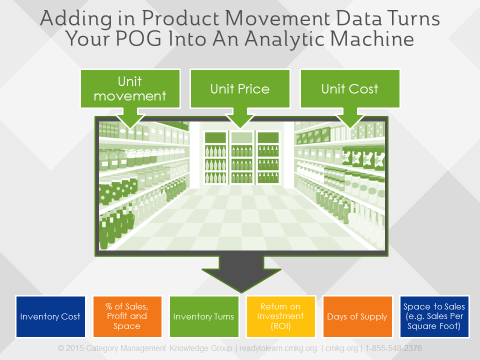

- Product data. By adding in unit movement, unit price and unit cost, your POG turns from a pretty picture into a highly analytic tool. Many organizations do not use the analytic side of POG development because of the extra time required to include the data. But without these inputs, you can’t take advantage of the multitude of other capabilities and functionality of planograms.

POGs relate to the product supply chain

When you think about POGs do you think about product supply chain? Well, you should.

Effective planograms can have huge synergies with the product supply chain, where efficiencies can be gained through planogram integration.

By effective, I mean planograms rely on the right inputs (from #2 above). Some Retailer’s ordering systems rely on authorized product distribution lists detailing which products should be in which stores, PLUS the shelf capacity data from planograms.

The result?

Just-in-time orders that are automatically placed accurately, without incurring overstocks. Other benefits include more efficient order picking at distribution centers, pallet builds in planogram order for more efficient store receiving and stocking, and the ability to calculate full loads by determining which products they will need soon.

Remember that product supply efficiencies affect Retailer's and Vendor's cost of goods sold – but is often overlooked when developing POGs.

In net, a planogram is only as good as the inputs. Up-to-date and accurate planograms contain detailed records of every product, fixture and position that is intended to be merchandised in every store. As established above, analytic POGs can have huge synergies with the product supply chain.

There’s incredible new technologies that continue to evolve, including measuring planogram compliance at store level, linking POGs to a Retailer’s in-store shopping assistance system, and through Shopper’s mobile devices. But investment in these new technologies is only going to be as good as the POGs developed. Remember to begin with a broader, more strategic understanding of the shelf.

Need a more strategic plan for the shelf — either as a Retailer or Manufacturer?

Space Management: Space Optimization and Advanced Technologies Master’s Training may be right for you. Chat now (click the GET HELP tab to the right) to answer your questions, or purchase online.